In demanding industrial environments, safety and structural reliability are non-negotiable. Facilities such as power plants, refineries, manufacturing units, and offshore platforms require components that can withstand heavy loads, extreme temperatures, and corrosive conditions. The performance of every structural element—from flooring to walkways—directly impacts operational efficiency, worker safety, and compliance with global safety standards.

Among the many materials and systems used to create secure and functional workspaces, metal gratings stand out for their adaptability and resilience. Especially in settings where heavy machinery, chemical exposure, and high foot traffic converge, selecting the right grating solution is critical. That’s where stainless steel, with its inherent strength and corrosion-resistant properties, becomes the material of choice for long-lasting and low-maintenance industrial components.

Unlike traditional carbon steel or aluminum alternatives, Stainless Gratings offer a unique blend of mechanical integrity, corrosion resistance, and aesthetic value. Whether installed in petrochemical plants, marine docks, or food processing units, stainless steel gratings provide unmatched longevity and reduced lifecycle costs. This makes them ideal for both safety-critical infrastructure and demanding architectural applications in GCC regions like the UAE, Saudi Arabia, and Qatar, where harsh climates require robust construction materials.

What Are Stainless Gratings?

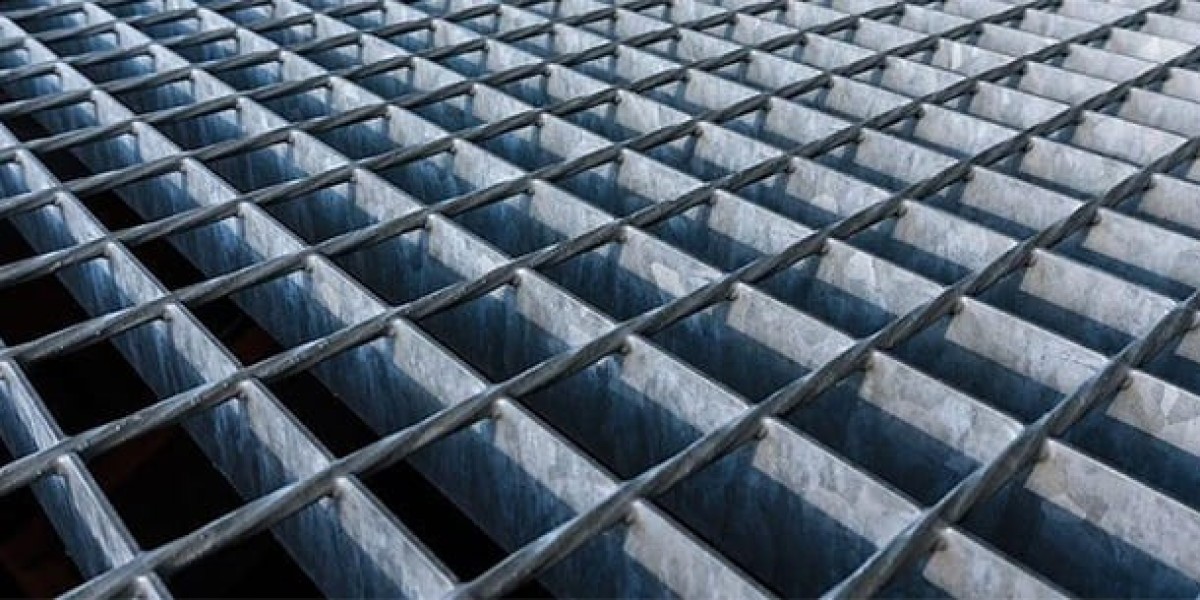

Stainless gratings are structural components made from high-grade stainless steel, commonly in grades 304 and 316. These gratings are designed in grid or mesh patterns that allow for superior load-bearing capabilities, drainage efficiency, and slip resistance. Manufactured using welding, press-locking, or swaging techniques, they can be tailored to meet specific industrial or architectural demands.

Their simple yet functional design typically features a series of parallel bars intersected by crossbars, forming a durable framework. This open-grid structure is highly effective in environments that demand ventilation, heat dissipation, or fluid drainage. These characteristics make stainless gratings a preferred solution for mezzanine flooring, catwalks, trench covers, and maintenance platforms.

Key Advantages of Stainless Steel Gratings

Stainless steel gratings offer several advantages that directly contribute to safety, longevity, and operational efficiency.

1. Corrosion Resistance

One of the primary reasons industries choose stainless steel is its excellent resistance to rust, chemicals, and saltwater. This makes stainless gratings especially effective in coastal regions, chemical processing plants, and food-grade environments where exposure to moisture and acidic substances is constant.

2. High Load-Bearing Capacity

These gratings are engineered to support heavy machinery, frequent forklift movement, and large volumes of pedestrian traffic without deforming or cracking. Their structural strength ensures stability, even under extreme pressure, making them ideal for industrial and construction applications.

3. Low Maintenance

Stainless steel does not require painting, sealing, or specialized coatings. It is easy to clean and does not accumulate bacteria or mold, which is particularly important in hygienic industries such as pharmaceuticals and food processing.

4. Fire and Heat Resistance

Stainless steel can withstand high temperatures without warping or weakening. This is a significant safety feature in environments where flammable materials are present or where heat exposure is routine.

Improving Workplace Safety

Accidents and injuries due to slippery surfaces, structural failures, or poor drainage are common in industrial environments. Stainless gratings help mitigate these risks with anti-slip surfaces and proper load distribution. Their open-grid design prevents the accumulation of liquids, reducing the chances of slipping or tripping.

Additionally, stainless steel's fire-resistant properties add an extra layer of safety in volatile environments. The combination of structural stability and corrosion resistance ensures that walkways, platforms, and stairs remain secure over time, even in high-risk conditions.

Cost-Efficiency and Long-Term Value

While the initial investment in stainless gratings may be higher compared to galvanized or carbon steel, the long-term return on investment is far greater. Their durability means fewer replacements, minimal maintenance, and reduced downtime—making them a cost-effective solution over the product lifecycle.

In regions like Dubai, Abu Dhabi, and Doha—where large-scale infrastructure projects and harsh environmental conditions converge—builders prioritize materials that meet stringent project timelines without sacrificing durability. Stainless gratings align with these needs, helping project managers reduce operational costs while adhering to environmental standards.

Industry Applications

Stainless steel gratings are used across a broad range of industries:

1. Oil and Gas

Platforms, stairways, and walkways in offshore rigs and refineries depend on corrosion-resistant materials. Stainless gratings perform reliably even in saline, humid, and chemically aggressive atmospheres.

2. Power Generation

Power plants utilize stainless steel platforms and trench covers due to their heat resistance and mechanical strength.

3. Food and Beverage

Hygiene is a priority in food-grade facilities. Stainless gratings support easy cleaning and resist bacterial buildup, meeting FDA and EU standards.

4. Chemical and Pharmaceutical

In highly corrosive environments, the resilience of stainless steel ensures uninterrupted operations and regulatory compliance.

5. Architecture and Urban Design

Used in facades, sunshades, and pedestrian walkways, stainless gratings offer a sleek, modern aesthetic while delivering structural function.

Customization for Specific Needs

Stainless gratings are highly customizable. Manufacturers can fabricate them in various thicknesses, sizes, and surface finishes—such as polished, brushed, or patterned—to meet project-specific requirements. Depending on the application, gratings can also include serrated surfaces for additional grip or be treated with anti-slip coatings for extra safety.

Installation options include bolted frames, adjustable mounts, and locking systems to ensure secure and seamless integration with other building elements. This flexibility is crucial in tailored architectural designs, offshore installations, and complex infrastructure systems.

Sustainability and Environmental Benefits

In today's sustainability-driven world, stainless steel offers a recyclable, low-impact material choice. It can be reused or reprocessed without losing its properties, making stainless gratings a green alternative. In eco-conscious markets like the UAE, Qatar, and Bahrain, selecting environmentally responsible materials is increasingly becoming a legal and corporate requirement.

Furthermore, the long lifespan of stainless steel reduces the need for frequent replacements, minimizing construction waste and aligning with LEED and other green building standards.

Conclusion

Stainless gratings represent more than just a flooring option—they are a strategic investment in safety, durability, and efficiency. From industrial plants and marine facilities to high-end architectural projects, these gratings deliver robust performance in the face of constant stress, moisture, and wear.

As industries evolve and the demand for sustainable, high-performance materials rises, stainless steel will continue to lead the way. By integrating stainless gratings into your infrastructure, you ensure long-term functionality, reduce operational risks, and meet modern safety and design standards.

Whether you're a project consultant in Abu Dhabi, a facility manager in Riyadh, or an architect designing for a coastal resort in Muscat, stainless steel gratings provide the reliability and value your project needs—today and well into the future.